- Latest news

- Database Update Crash Recovery System March 2025

- Online CRS Database: No more manual updates!

- Database Update Crash Recovery System February 2025

- Bliksund’s bold expansion

- Database Update Crash Recovery System January 2025

- Update in our Crash Recovery System

- Show or hide CRS buttons and categories

- Database Update Crash Recovery System December 2024

- Database Update Crash Recovery System November 2024

- Handle with Care: Navigating Complex Car Doors with CRS

- Latest news

- Database Update Crash Recovery System March 2025

- Online CRS Database: No more manual updates!

- Database Update Crash Recovery System February 2025

- Bliksund’s bold expansion

- Database Update Crash Recovery System January 2025

- Update in our Crash Recovery System

- Show or hide CRS buttons and categories

- Database Update Crash Recovery System December 2024

- Database Update Crash Recovery System November 2024

- Handle with Care: Navigating Complex Car Doors with CRS

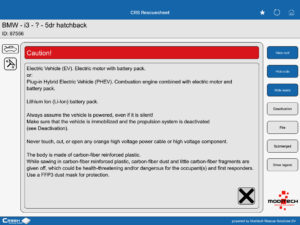

Increasing use of carbon fibre by the vehicle industry

Where carbon fibre, often referred to as carbon, was used in the past mainly in racing cars and exotic supercars, it is now increasingly being used in cars for the general public. This is not surprising because carbon fibre is in many respects the ideal material for use in cars.

What exactly is carbon fibre?

Carbon fibre is a material consisting of extremely thin fibres of carbon. It is mainly used as reinforcement in synthetic resin to manufacture very strong and light composites. It is much lighter than steel, much stronger and does not rust.

Advantages of use

As mentioned, carbon fibre is much lighter than steel. Supercar manufacturers are therefore only too happy to use carbon fibre to save weight. For example, McLaren, Pagani and Koenigsegg use a carbon fibre monocoque for each model, with Ferrari even using four types of carbon fibre on the LeFerrari. Some supercars are also available as ‘Full Naked Carbon’, where the carbon fibre is visible throughout the entire car.

The weight savings is the reason why more and more electric vehicle manufacturers are applying carbon fibre in their products. Battery packs are very heavy, so weight reduction is more than welcome, thereby reducing energy consumption and increasing range. BMW was the first mass producer to use carbon fibre on a large scale in its i3 and i8 models. Carbon fibre ceramic brakes and a carbon fibre roof are now optional on a good number of other cars.

Dutch company Ebusco has developed a fully electric city bus made of carbon fibre. The use of carbon fibre means that the bus weighs less than a regular one and can cover a greater distance on the same amount of electricity. We expect to add the unique Ebusco 3.0 to the Crash Recovery System shortly.

Hazards for first responders

If a vehicle’s chassis (and/or body parts) consists of carbon fibre reinforced plastic, first responders need to bear this in mind when cutting it. Small splinters and vapour are released, which may be dangerous for occupants and first responders. Therefore, always use an FFP3 dust mask for protection.

Crash Recovery System – Know what’s inside, see what to do!