- Latest news

- Database Update Crash Recovery System March 2025

- Online CRS Database: No more manual updates!

- Database Update Crash Recovery System February 2025

- Bliksund’s bold expansion

- Database Update Crash Recovery System January 2025

- Update in our Crash Recovery System

- Show or hide CRS buttons and categories

- Database Update Crash Recovery System December 2024

- Database Update Crash Recovery System November 2024

- Handle with Care: Navigating Complex Car Doors with CRS

- Latest news

- Database Update Crash Recovery System March 2025

- Online CRS Database: No more manual updates!

- Database Update Crash Recovery System February 2025

- Bliksund’s bold expansion

- Database Update Crash Recovery System January 2025

- Update in our Crash Recovery System

- Show or hide CRS buttons and categories

- Database Update Crash Recovery System December 2024

- Database Update Crash Recovery System November 2024

- Handle with Care: Navigating Complex Car Doors with CRS

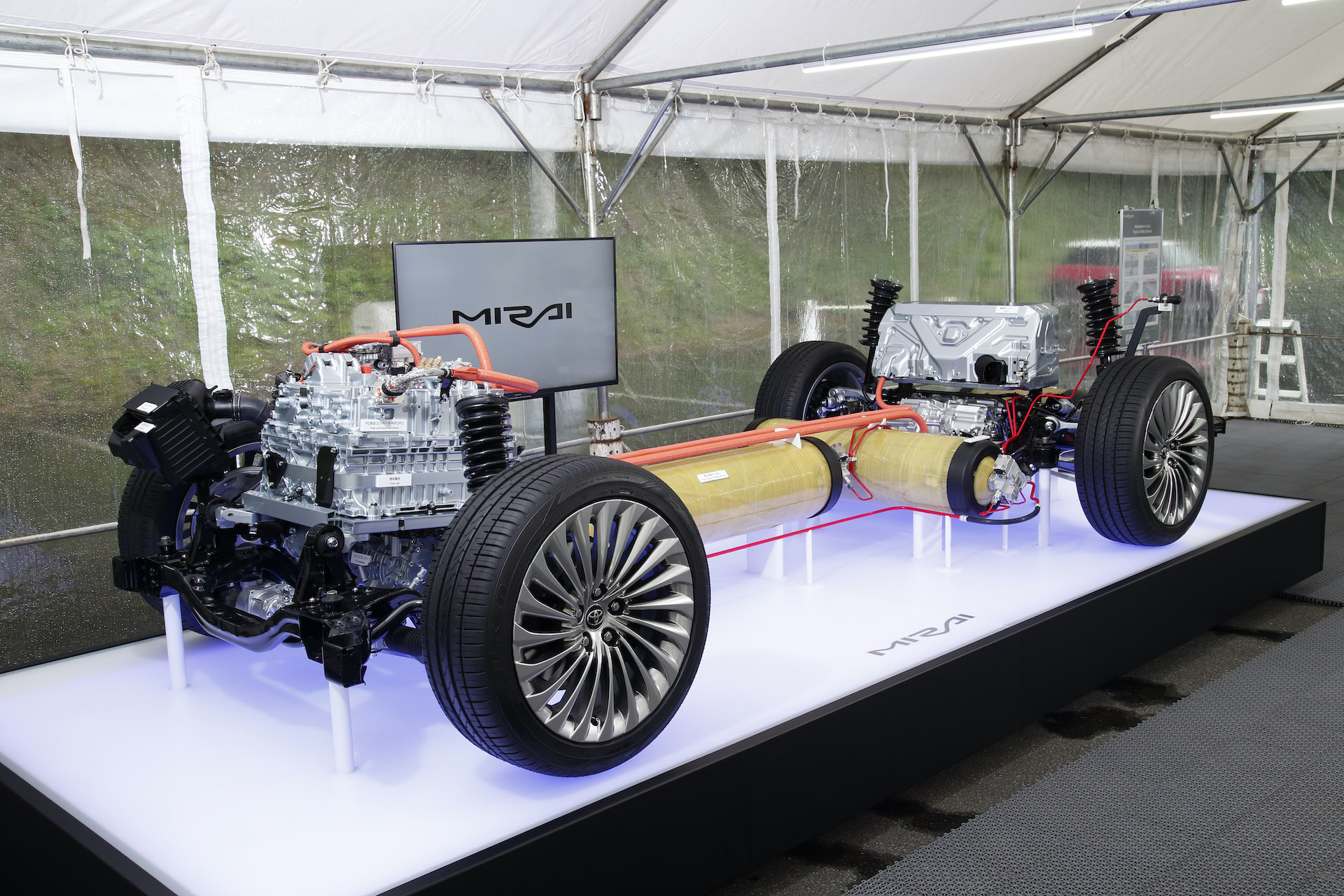

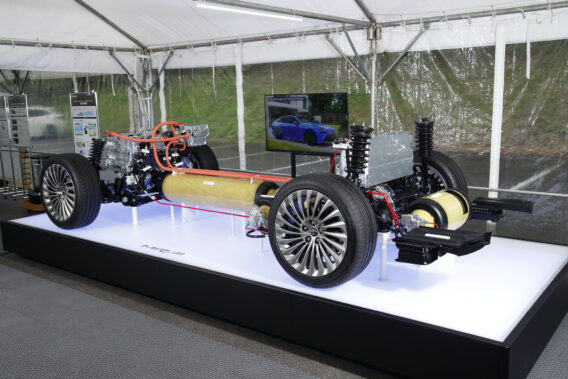

CRS preview: the Toyota Mirai fuel cell electric vehicle

Toyota presented the second generation of its revolutionary Mirai at the Los Angeles Auto Show. The fuel cell electric vehicle (FCEV) offers a greater range of up to 650 kilometres, with the only emission being water vapour. Refuelling only takes a few minutes, just like with a traditional petrol and diesel car. The sale of this technically very complex car will start at the beginning of 2021.

Toyota presented the second generation of its revolutionary Mirai at the Los Angeles Auto Show. The fuel cell electric vehicle (FCEV) offers a greater range of up to 650 kilometres, with the only emission being water vapour. Refuelling only takes a few minutes, just like with a traditional petrol and diesel car. The sale of this technically very complex car will start at the beginning of 2021.

Toyota began developing its first FCEV back in 1992. This led to the launch of the Toyota Mirai in 2014, the world’s first hydrogen vehicle designed as such. As soon as this technically very complex model came on the market, it was included in the Crash Recovery System. The arrival of this exceptional vehicle is in large part due to Toyota’s many years of experience with hybrid technology, the core technology of a wide range of electric vehicles, including FCEVs. The Japanese car brand believes in the power of hydrogen as a viable and abundant source for transport and storage of energy. It has the potential to provide zero-emission mobility, not only in terms of cars, but also trains, ships and aircraft.

Technology at a higher level

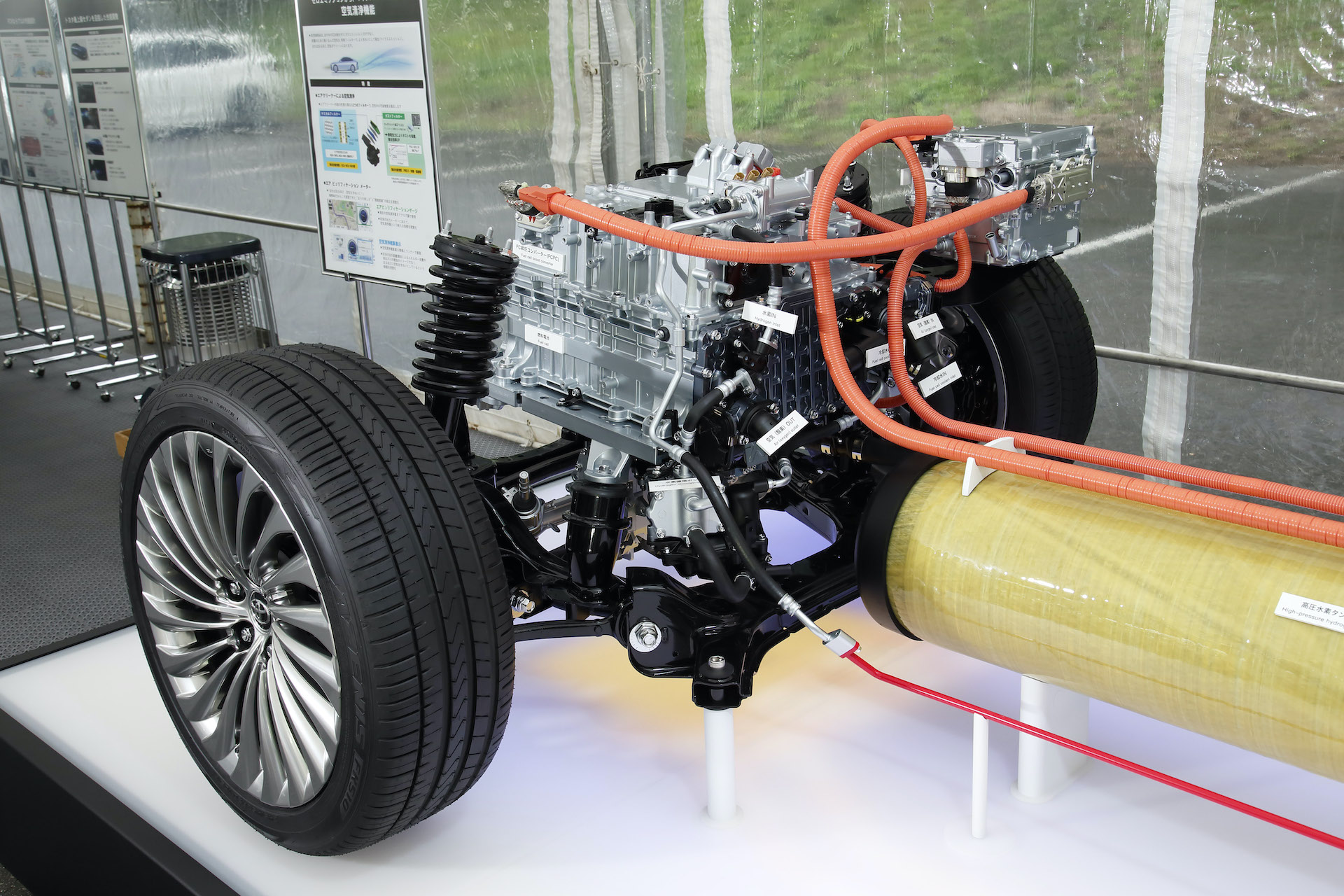

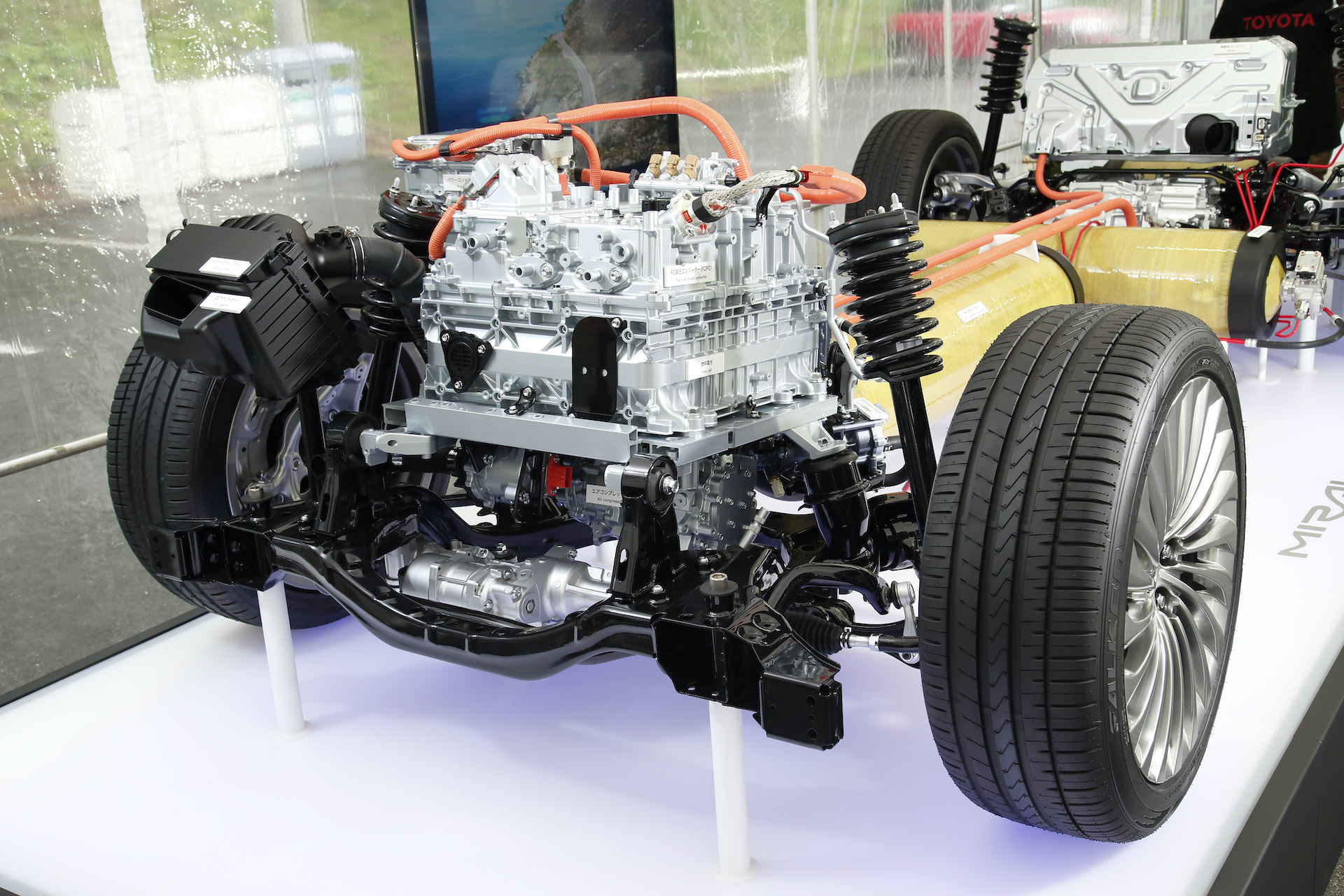

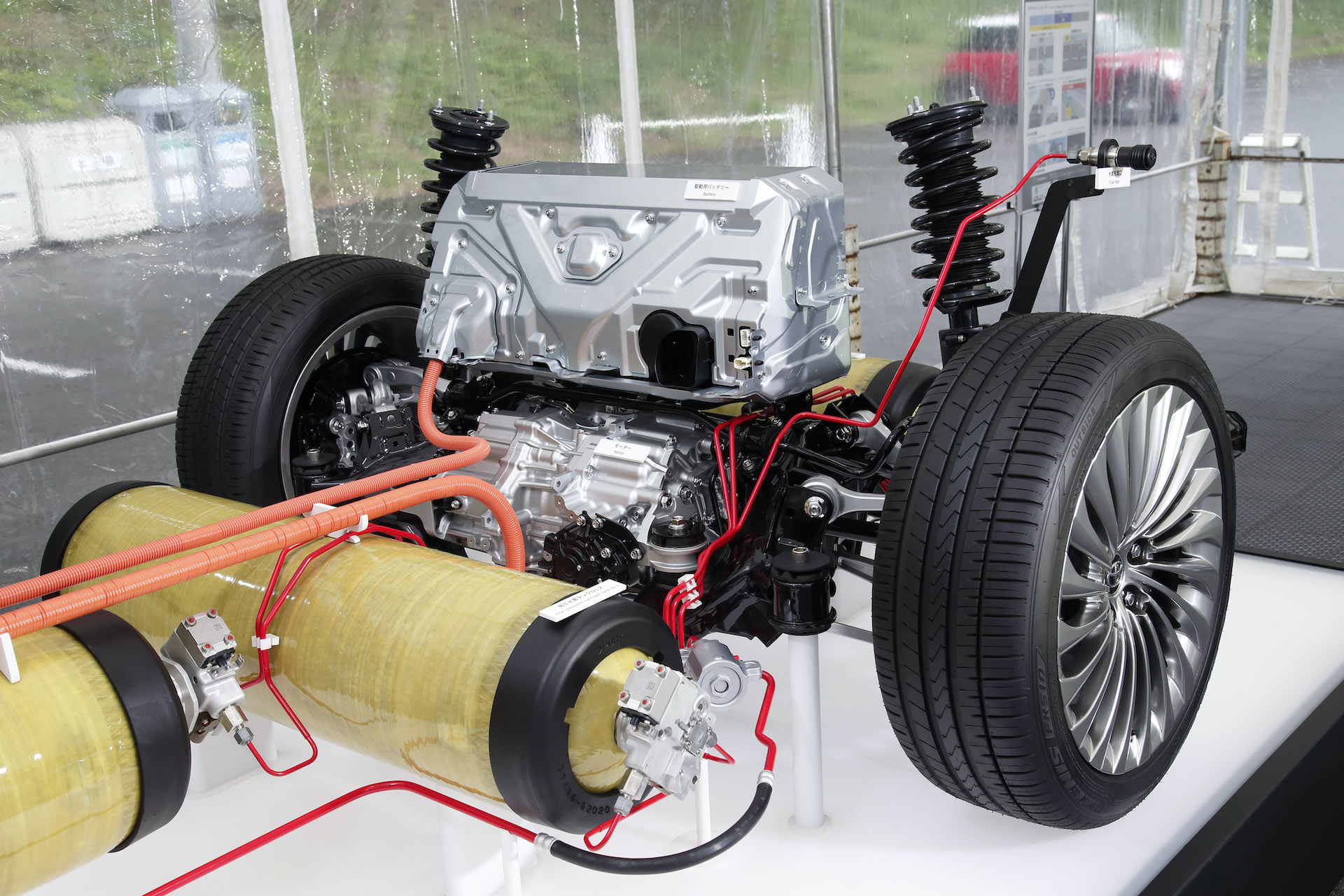

The new generation of Mirai takes FCEV technology to an even higher level. The fuel cell system has been thoroughly overhauled. Smarter housing, more power, better efficiency and more space for hydrogen storage have resulted in a greater range of approximately 650 kilometres, an increase of 30 percent compared to the first generation. The Toyota Mirai is based on the new modular GA-L rear-wheel drive platform designed according to Toyota’s TNGA (Toyota New Global Architecture) philosophy. We are familiar with this platform from the Lexus LS; the Mirai, however, has slightly smaller proportions. The fuel cell has been moved further forward, closer to the engine compartment. This made it possible to integrate three hydrogen tanks instead of the current two. This is one of the reasons why the action radius is a lot larger. The battery and electric motor are located above the rear axle, which has a positive effect on the weight distribution of 50:50.

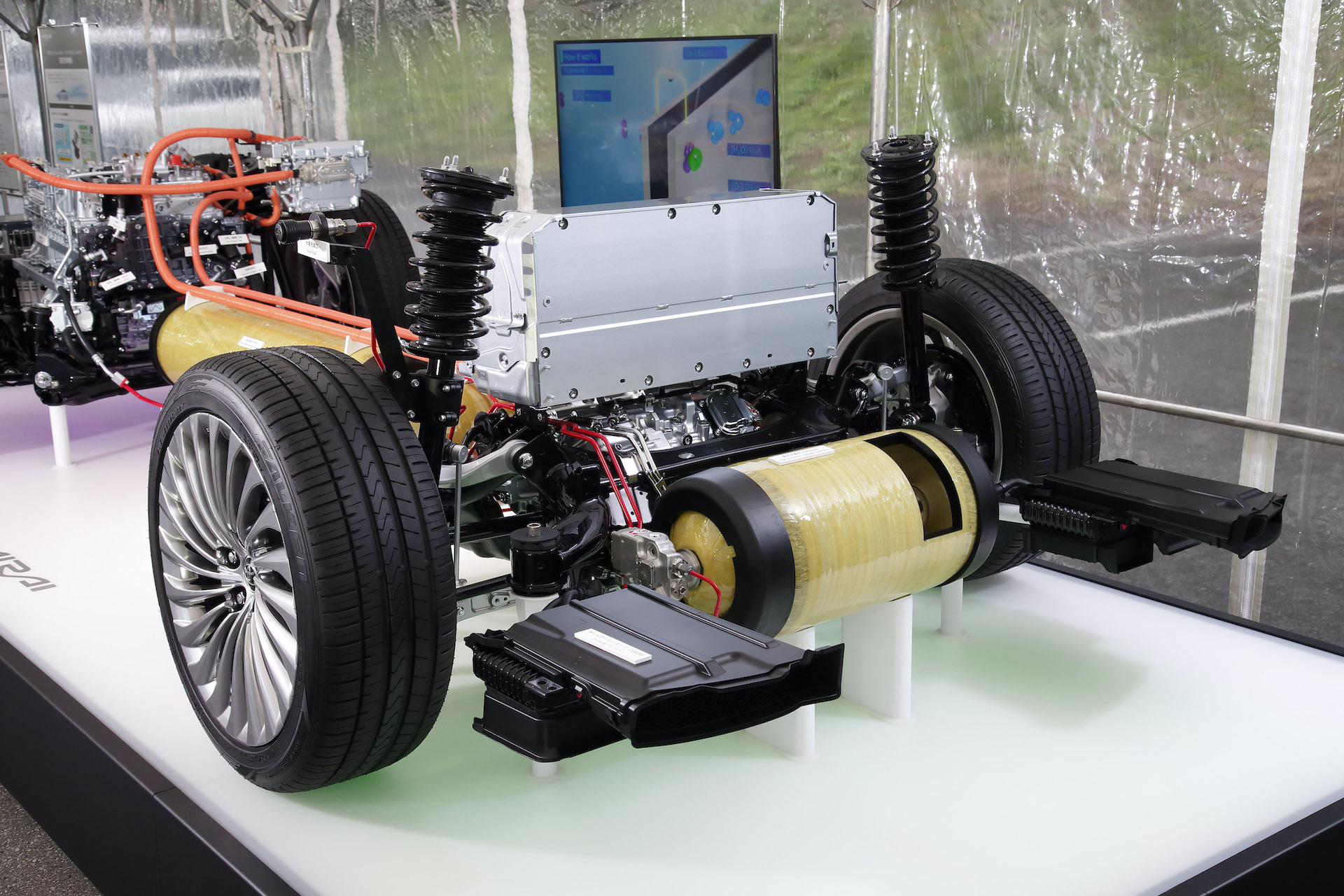

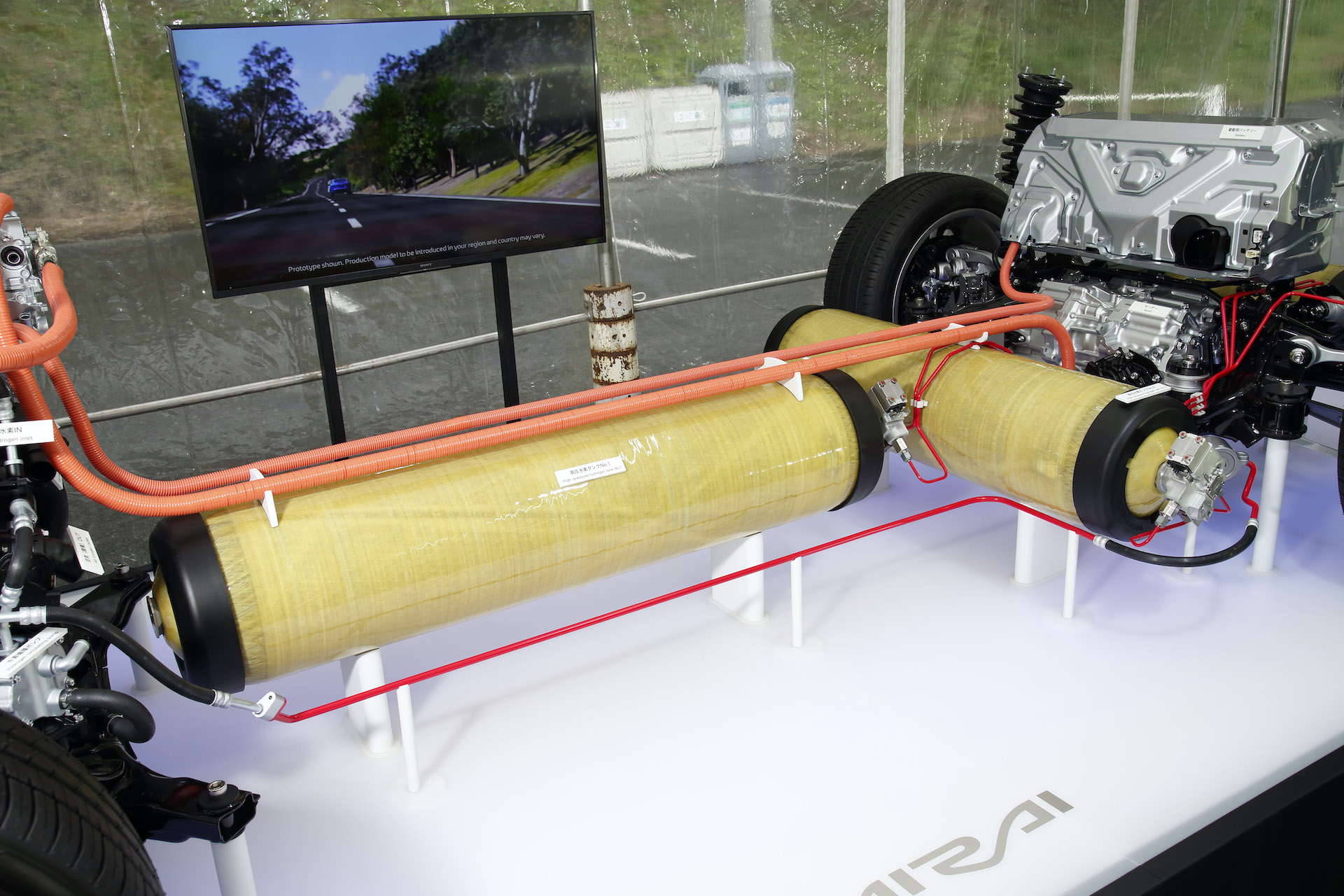

Three hydrogen tanks

The hydrogen tanks are arranged in a T-configuration with the longest one mounted lengthwise and running centrally under the vehicle floor. The two smaller hydrogen tanks are located laterally in the area under the rear seat and luggage compartment as can be clearly seen in the attached images. Together, the three tanks can hold 5.6 kg of hydrogen – in the first-generation Mirai it was 4.6 kg in two tanks. The position of the hydrogen tanks contributes to the lower centre of gravity of the car and does not take up luggage space. The lightweight hydrogen tanks have an even stronger multi-layer construction. Toyota was able to increase body stiffness by adding strategically placed reinforcements and increasing the use of body adhesives and laser screw welding.

More power

Toyota developed the fuel cell and fuel cell power converter (FCPC) specifically for the Mirai’s GA-L platform. The engineers succeeded in bringing all elements together in a stacking frame, including the water pumps, intercooler, air conditioning, air compressors and hydrogen recirculation pump. Each part is also smaller and made up to 50 percent lighter, while the performance has been improved by up to 12 percent. The fuel cell is more compact than in the previous Mirai and has fewer fuel cells (330 instead of 370). Nevertheless, the power density of 5.4 kW/l is much better. The system power has also increased from 114 to 128 kW. Furthermore, the performance in very cold weather conditions is improved, even at -30 degrees Celsius. The fuel cell now also includes the Fuel Cell DC-DC Converter (FDC) and certain high voltage modular components.

Lithium ion battery

The new Mirai is equipped with a small lithium-ion (Li-ion) high-voltage battery instead of the first-generation nickel metal hydride (NiMH) type. Among other things, this is to recover and reuse braking energy. Although it is smaller, it has a higher energy density, resulting in higher output and superior environmental performance. The battery consists of 84 battery cells and has a nominal voltage of 310.8 compared to 244.8 of the previous Mirai. The capacity is 6.5 Ah instead of 4.0 Ah. Thanks to the smaller dimensions, the battery has been moved from the luggage compartment to just behind the rear seat. Subtle inlets on both sides of the rear seat provide sufficient cooling.

Market forecast

According to Toyota, sales are expected to exceed those of the previous generation by a factor of ten. The carmaker has sold approximately 10,000 units of the first generation Mirai, which means that 100,000 car sales are now expected. The sales price that is 20% lower should contribute to this.

Hydrogen technology is becoming more attractive in general because of its suitability for daily use, but also increasingly important in the search for solutions for clean mobility. The practical application of FCEVs will also steadily increase as markets improve their hydrogen infrastructure, the number of refuelling stations increases and governments and local authorities introduce new incentives and regulations for cleaner mobility. As a result, emergency service workers will increasingly have to deal with these types of vehicles.

Currently, the Crash Recovery System describes more than 40 different hydrogen-powered vehicles, such as the BMW Hydrogen 7, the Honda Clarity and the Mercedes F-Cell. It also describes several hydrogen-powered buses, such as those from the manufacturers Van Hool (type A 330) and VDL.

Crash Recovery System – Know what’s inside, see what to do!

[More about hydrogen technology in this article about Shell and this article about Hyundai]